Full range water purification with the goal to supply drinking water.

NVAqua is a system which aims to provide drinking-water. The device NVAqua can be used to treat surface waters containing a low DCO and a low DBO5 amount (rivers, lakes, sources…). If salts are present in the water, nanofiltration or reverse osmosis can be added.

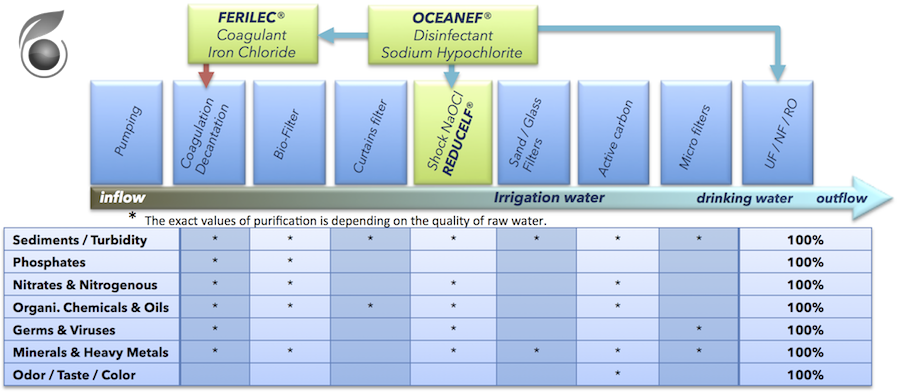

The main steps of a NVAqua unit are described below. The below picture hereafter shows how the different modules are combined. The number of modules is depending on the inflow water quality as well as the outflow water quality requested.

- Coagulation with Ferilec produced in situ, The iron oxi-hydroxide is produced in the FERILEC unit via electrolysis of metal iron and bleach produced in-situ. The iron oxi-hydroxide (Ferilec) is used as a coagulant for the removal of the MES in the effluent and also a part of the phosphate present in the water. During the coagulation phase, metal salts such as As, Zn and Al are removed. A decantation unit recovers the sludges produced.

- Biofiltration, the biofiltration comprises an aerobic filter filled with bacteria followed by an anaerobic one. In the aerobic filter, air is injected in the effluent and nitrification occurs: the ammonium is transformed into nitrite and nitrate. In the anaerobic filters, denitrification occurs: nitrites and nitrates are transformed into N2. During this bactériological process, organic compouds are degraded and Carbon is removed.

- Disinfection with hypochlorite produced in-situ, the aim of this operation is to remove any bacteria and viruses, this process is called shock-chloration. The manganese and cyanides are also removed.

- REDUCELF: the Reducelf unit is reducing any hypochlorite and chloramines remaining in the effluent (they are produced during the shock treatment).

- Activated Media Filtration (AMF), any big particles such as Iron oxides remaining in the effluent are removed in the bed of the activated glass filter.

- Activated Carbon Filtration, the remaining chloramines which may have been formed during the shock-chloration step as well as any chlorine and hypochlorite, are removed by the AC-filter. Micropollutants such as medical compounds, phenols and HPA are also retained. This step improves color, taste and odor of the water.

- Microfiltration removes part of the resistant bacteria and colloides fixed on fine particles, as well as carbon particles from the AC-filter.

Depending on the quality of the inlet water, the following finishing treatments can be added:

- Ultrafiltration. Ultrafiltration removes any remaining viruses, organic macromolecules, as well as dissolved organic compounds. It also eliminates residual turbidity.

- Nanofiltration: Nanofiltration removes any multivalent ions (sulfates, phosphates, calcium, Zn2+, Al3+ .. ) as well as pesticides.

- Reverse Osmosis: Reverse osmosis removes monovalent ions such as nitrates, Na+, Cl– as well as HAP and heavy metals

- Oceanef: The Oceanef unit produces bleach used in the process (for the production of Ferilec coagulant and for the Reducelf), but this bleach can be recovered and sold for domestic disinfecton applications. The Oceanef uses a saturated salt NaCl solution to produce bleach via electrolysis.

The NVAqua units can be customized:

· NVAqua UF-480: 500 m3 / day, with ultrafiltration,

· NVAqua UF-100: 100 m3 / day, with ultrafiltration,

· NVAqua Z-100: 100 m3 / day, with sand-zeolite filtration.